Innovation is crucial to the growth in the field of medical devices. Bringing groundbreaking concepts to life requires a trusted partner who can transform ideas into tangible prototypes and, ultimately, high-quality production parts. Influx Labs steps in to fulfill this crucial function, offering a complete solution for medical device companies that want high-quality prototype manufacturing as well as CNC cutting.

Influx Labs facilitates medical device design from concept to prototype

The journey of a medical device manufacturer from its initial idea to the moment it is launched on the market is not easy. Influx Labs recognizes the value prototyping as a part of this process. They provide a friendly and supportive atmosphere that allows you to transform your creative concepts into prototypes that you can test which allows you to refine and collect feedback before committing large-scale production.

Influx Labs Expertise on CNC Machining

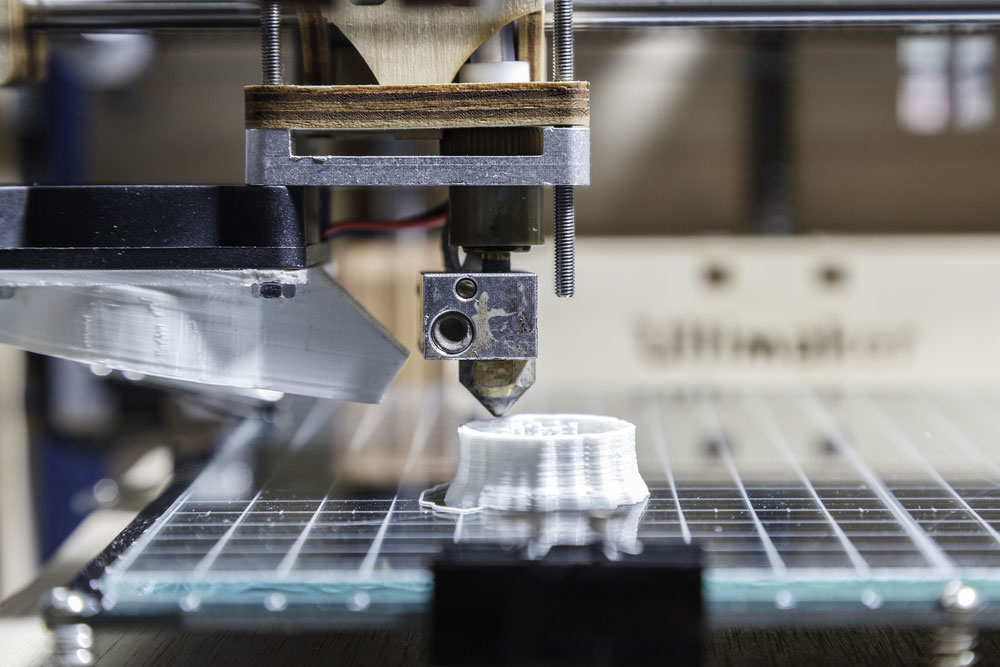

Influx Labs’ core competency is their cutting-edge CNC manufacturing technology. Computer Numerical Control (CNC) machineries employ computer-aided commands to precisely control the cutting tool. This allows for extremely accurate and complex parts to be designed. This technology permits Influx Labs to craft medical device prototypes and production parts that are in compliance with the strictest medical device standards.

Beyond Prototyping: Scaling up for Production

Influx Labs’ services extend beyond rapid prototyping. Their experience in CNC machine tools allows them to seamlessly switch from prototyping to high-volume production runs. This makes it unnecessary to search for a different manufacturing partner. The whole process is made easier and accuracy between the prototype and final product is assured.

Our unwavering commitment to quality: Traceability of the material and Certifications

Influx Labs recognizes the critical importance of quality in the medical device industry. They have a strict system that ensures full traceability of materials throughout their entire process. This will ensure that you have full transparency regarding the materials used in the creation of prototypes and parts. Furthermore, Influx Labs can provide materials and finishing certificates upon the request of the customer, ensuring security and ensuring that you meet rigorous regulatory requirements. Get a quote at Machine Shop

Why choose Influx Labs to meet your medical device needs?

Certain factors make Influx Labs apart from other manufacturing and prototyping firms. What makes Influx Labs an ideal partner for your medical device development?

Influx Labs has a special concentration on medical equipment. They know the demands that are unique to this field. They have the expertise and expertise required to manufacture high-quality components for medical devices.

Precision Engineering: Advanced CNC capabilities ensure consistency in results and unparalleled accuracy crucial for creating functional and reliable equipment.

Influx Labs provides a seamless transition between prototyping and manufacturing, saving time and money by removing the need to look for different vendors.

The Quality Commitment: Influx Labs is committed to quality, from material traceability to certifications. We make sure your medical devices meet strict standards.

Influx Labs accelerates your medical device development journey

Influx Labs is a leader in prototype manufacturing, CNC machining and medical device development. This knowledge lets companies develop new products more quickly and with greater efficiency. In partnering with Influx Labs, you gain access to:

Reduced Risk: Prototyping allows you to find issues and solve these issues before they occur in the design phase, minimizing any risk in the event of full-scale production.

Influx Labs’ streamlined prototyping and production enables you to bring your medical device faster to market.

Improved design refinement prototyping: Prototypes are an excellent opportunity to test your design and gather feedback from the user. This allows you to enhance it with greater confidence.

Make a partnership with Influx Labs and unlock the capabilities of rapid prototyping as well as precise CNC machining. Watch as your medical device innovations become reality and define the future of healthcare.

Leave a Reply